The design of controllers and the simulation of the closed-loop system are studied for the processes explained in Chapter 2 of the book. Although the interactive tools include selected control techniques, the reader can solve exercises on these processes using these different interactive tools avaibalew in the Control system design group.

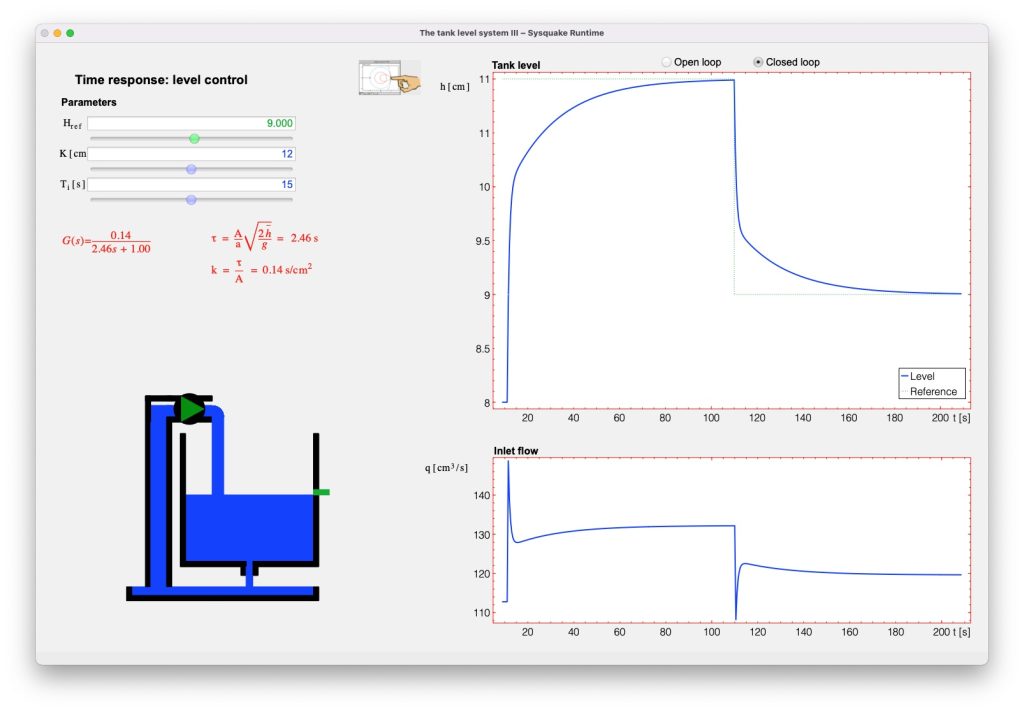

The tank level control

This tool deals with PI control of tank level. In this case, the closed-loop response of the controlled system is shown trying to keep interactivity features as much as possible.

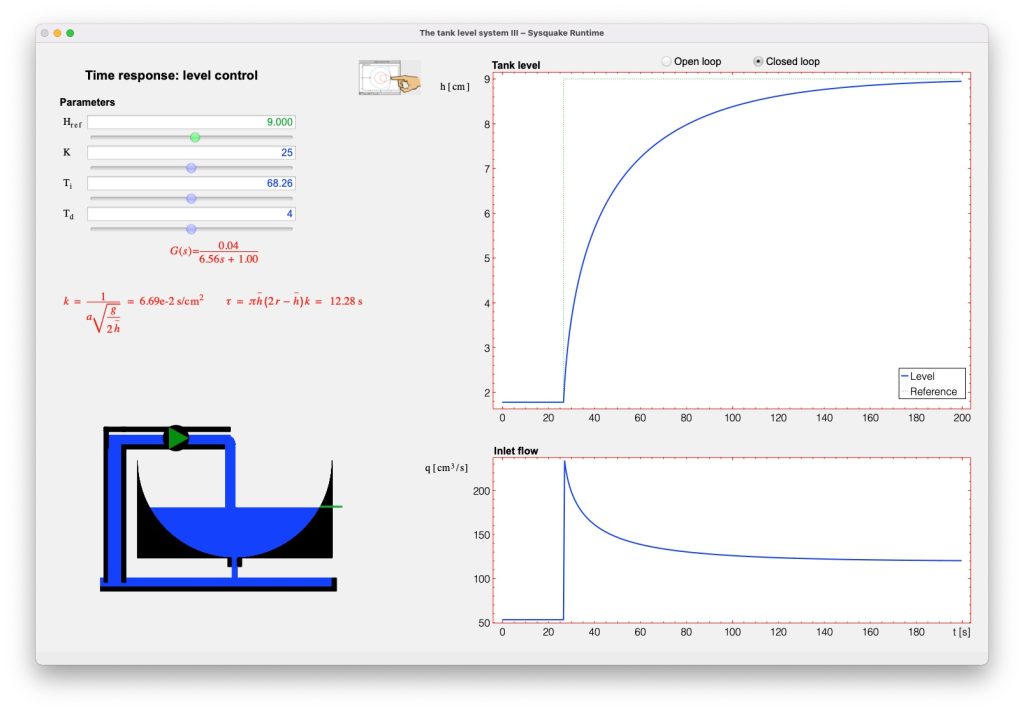

Variable section tank level control

In the application described in the interactive tool it is possible to simulate the closed-loop control of the spherical tank level system under PID control.

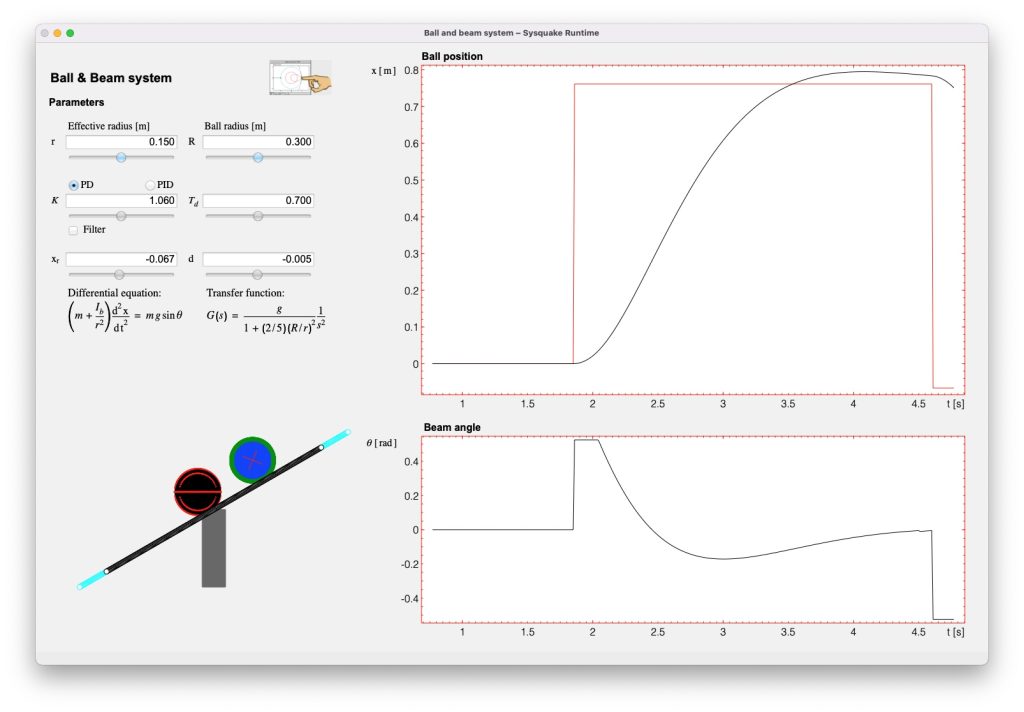

Ball & beam control

In the application described in the interactive tool it is possible to simulate the closed-loop control of the ball & beam system. Step changes in both the ball reference position and a load disturbance can be introduced to analyze the closed-loop response, both in terms of transient response and steady-state error. 1-DoF and 2- DoF PD and PID control structures can be selected, without or with a reference filter to cancel the closed-loop zeros.

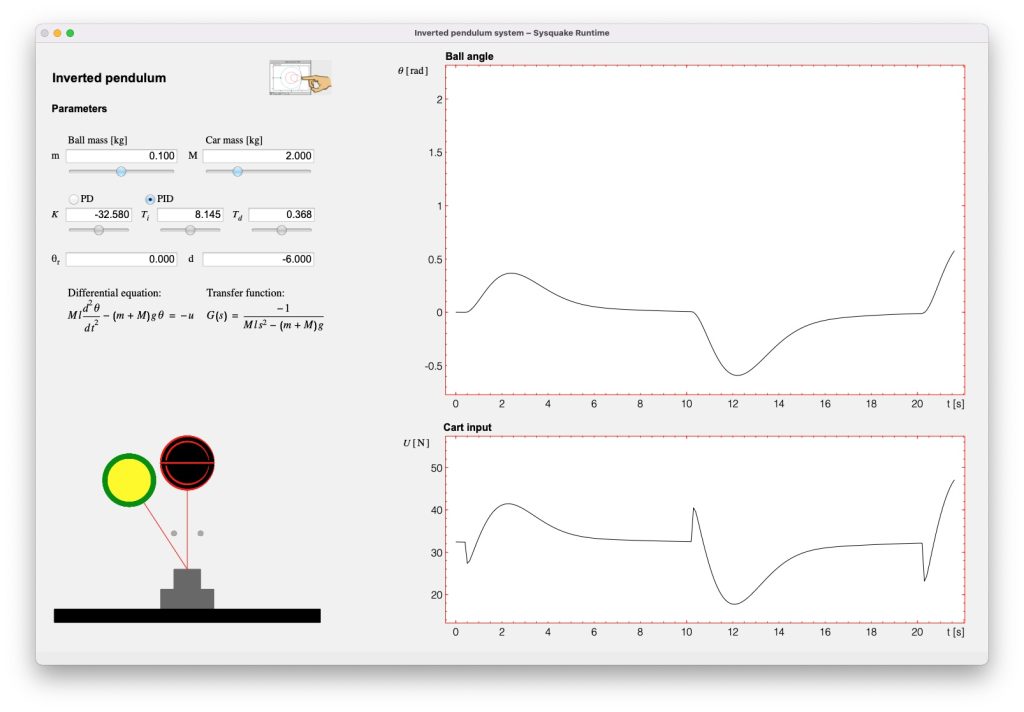

Inverted pendulum on a cart control

In the application described in the interactive tool it is possible to simulate the closed-loop control of the inverted pendulum on a cart system. In this case, only the dynamics relating the force applied to the cart to the ball angle are included in the analysis. Interactive PID design is used to stabilize the system and achieve zero steady-state error to load disturbance.

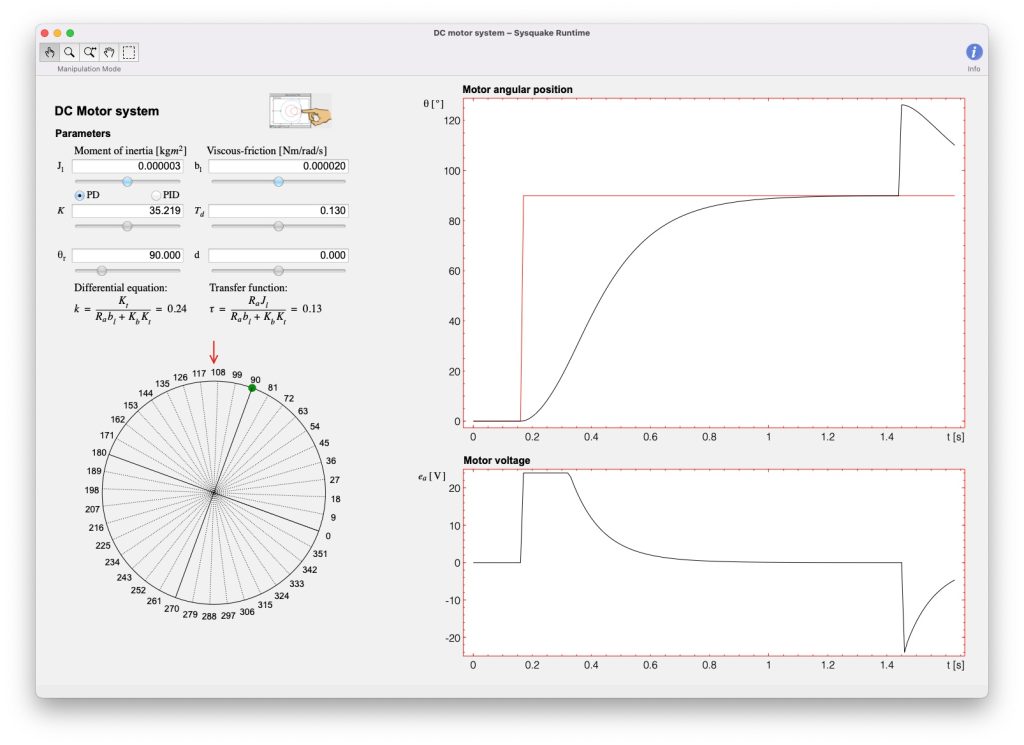

DC motor control

In the application described in the interactive tool it is possible to simulate the closed-loop control of the angular position of the DC motor. Ideal (non-interacting) PI and PID control are used in the face of changes in the angular reference and load disturbance (input voltage disturbance). Both transient and steady-state responses can be analyzed.