Nowadays, most countries are promoting the efficient use of energy and water (with focus on industrial, transport and building sectors) due to increasing demand and fostering the use of renewable energy to reduce costs and increase sustainability. Generally, energy efficiency is not only associated with technological improvements, but also with the improvement of control and energy management. This is the main framework of this research project ENERPRO.

This project deals with the analysis, design and application of modeling, control and optimization techniques (in the framework of hierarchical and model-based predictive control, MPC) to achieve an efficient energy (electricity and process heat/water), water and CO2 management in production environments with support of renewable energy and storage systems. Through optimal management of these resources and by adapting generation to demand, it should be demonstrated how automatic control allows to achieve cost savings and reduce the environmental impact on the operation of complex processes.

Around this theme, concepts like micro-grids (MG), related to the efficient use of electricity, renewable heat and cooling (RHC), in the area of primary energy supply from renewable sources and water efficiency (WE), around adequate use of water have arisen. The paradigm treated in this project goes beyond, since it treats comprehensive and coordinated management of those heterogeneous resources focusing on efficiency and economics. The problem is composed by different control and decision levels about the final use of the available energy based on different objectives (minimizing the use of conventional fossil energy sources, economic, environmental and quality aspects, etc.) This gives rise to a hierarchical control problem that requires coordination and cooperation between systems and that will be addressed using hierarchical and hybrid predictive control techniques, both in centralized and distributed versions. It will be also necessary to develop models, estimators and predictors of the energy generation and demand stages.

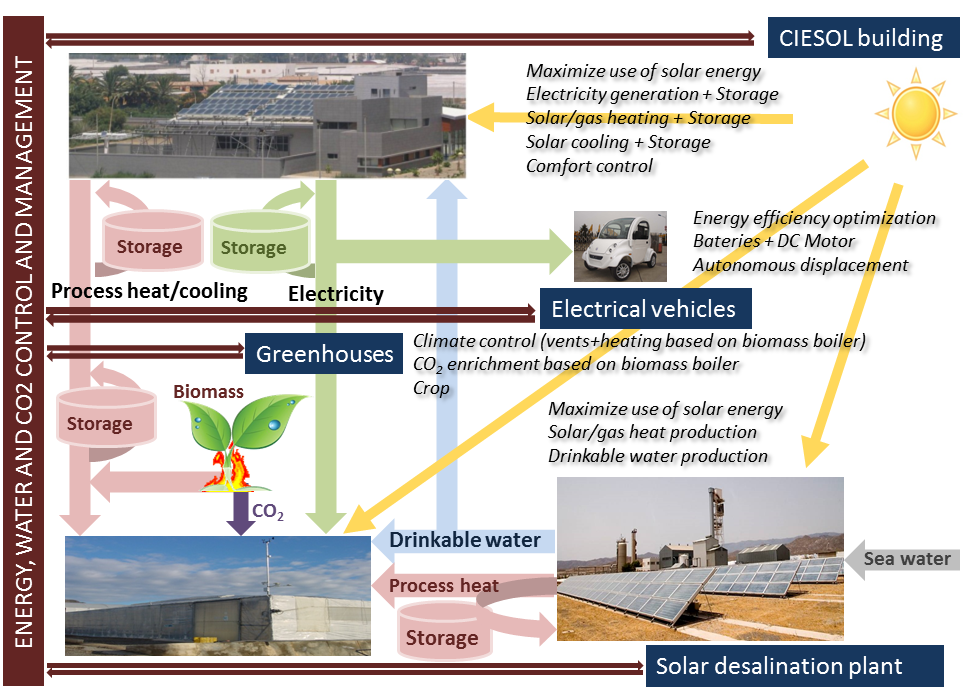

A key element of the project is that a real production system will be use as test-bed plant (including a bioclimatic building, a greenhouse, an electric vehicle and a solar desalination plant), on which the developed modeling and control techniques will be validated. On one hand, the CIESOL building provides electricity and process heat using solar collectors and a photovoltaic installation for feeding the building, greenhouse and electric car demand, storing the exceeding one. On the other hand, the desalination plant supplies drinkable water and process heat to the systems using solar energy. Moreover, through biomass combustion, both process heat and CO2 is generated within the greenhouse. In all cases energy has another auxiliary uses. A key factor is to try to adapt the demand to the production of energy (and vice-versa), where modeling, predictive control and supervision techniques play an important role. Thus, both low-level (systems and equipment level) and high-level (setpoint optimization, process coordination, dynamic real-time optimization) modeling and control objectives arise in this scope.

Research approach and functional diagram of the test-bed plant

The project aims to develop hierarchical MPC formulations for the optimal energy efficient and economic management of heterogeneous energy systems integrated in a production system. Since MPC is capable of providing optimal control strategies that guarantee the fulfilment of the operating constraints in spite of the incomplete information on future supplies and demands, it is considered here as the keystone for the enhanced management of production systems supported by renewable energies.

The three basic objectives of the coordinated project are:

- Development of methodologies for obtaining models of processes that contain renewable energy sources to produce/consume process heat, electricity, water and CO2. Development of estimators and predictors of generation and demand stages.

- Development of hierarchical, hybrid and, in general, MPC control and management strategies to optimize production from the economic, security and energy and water use points of view in heterogeneous systems, using a coordinated and comprehensive approach.

- Implementation and validation of the strategies in the production environment selected as test-bed plant. This will facilitate the development of the different tasks of the project over realistic conditions. Possible extensions to more complex environments like campus or industrial clusters will be demonstrated.

The fulfilment of the preceding goals represents a significant contribution with real impact in this class of processes as evidenced by the interest shown by firms like Fundación Cajamar, Unica Group SCA, Wagner Solar, Solar Jiennense, naming only a few. The proposal is also a natural continuation follow-up of previous work carried out the research groups integrating the project. The team has a remarkable experience in control systems backed by many papers published in some of the most cited scientific journals and relationships with international research teams.