DESCRIPTION

Thermal Energy Recovery from a Novel Sequencing Batch Biofilter Granular Reactor

Objective

Demonstrate the technical, environmental and financial feasibility of the THERBIOR technologies to improve energy efficiency in wastewater treatment plants using a fully off-grid solar-assisted heat pump hybrid system aplicable in Mediterranean tourism sector.

Expected technical results

- Development of an innovative, highly-efficient and cost-effective solution to reuse energy from wastewater in tourism sector.

- Better water managment and more efficient use of renewable energy potential in the wastewater sector in Europe.

- Daily monitoring of reused water and produced energy.

- Creation of new market oportunities in the water-reuse sector.

Expected environmental results

Increased water treatment process efficiency (e.g. low energy consumption and smaller footprints).

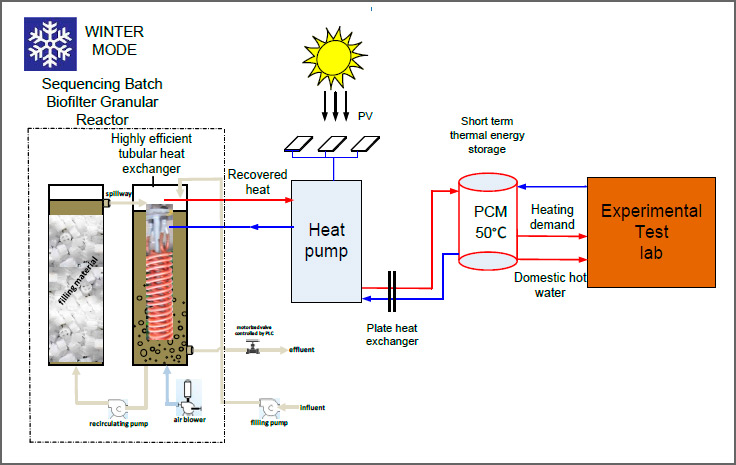

General scheme of the proposed system working in:

Description

Given the main characteristics of wastewater heat - availability, plentiful amounts, small temperature variations and being warm in winter yet cold in summer - it offers a low-grade thermal energy heat source that can be exploited for heating/cooling purposes in heat pump (HP) systems (CWWA, 20091 ; Frijns et al., 20132 ; Meggers and Leibundgut, 20113 ; Yaxiu et al., 20134 ).

Furthermore, bacteria in wastewater treatment plants (WWTPs) need oxygen to remove organic pollutants and this is provided by pumping air into the water through an air blower. The wastewater aeration process uses up around 50% of the total wastewater energy consumption (Tchobanoglous et al., 20025 ). Additionally, the introduction of new standards for pharmaceutical and health care product removal from water are likely to further increase energy consumption in WWTPs (Stillwell et al., 20106 ).

Therefore, efforts to reduce overall energy use in WWTPs have mainly concentrated on improving pumping and optimizing aeration. Thermal energy can be recovered from raw wastewater or effluent by exploiting the often significant temperature differential between wastewater and ambient conditions (Fiore and Genon, 20147 ). Over the last decade, heat recovery plants using wastewater have attracted interest in many countries. The first plant was built in 1987 and used heat from the water coming out of the Ochiai WWTP for air-conditioning in its administrative offices in Tokyo (Funamizu et al., 20018 ).

However, heat exchangers used in conventional WWTPs suffer from certain problems such as extracting the necessary heat from the water inlet to the activated sludge tank to allow microorganism survival as well as not being able to immerse heat exchangers in the activated sludge tank, where the heat gain would be greater; this is due to possible biomass fouling deposits. In this framework, the Water Research Institute (IRSA) of the National Research Council of Italy (CNR) recently developed a novel Sequencing Batch Biofilter Granular Reactor system, SBBGR, which combines the advantages of linked biomass systems (i.e. greater robustness and compactness) with those of periodic systems (i.e. greater flexibility and stability). It is a unique system in virtue of the particular type of biomass growing in it (a mixture of biofilm and granules packed in a filling material), which allows greater biomass retention in the reactor - up to one order of magnitude higher than that recorded in conventional biological systems.

This feature (extended sludge duration) allows the microorganisms to spend more time in the catabolic part of the metabolism phase, thus releasing the energy stored in the pollutants in the liquid phase. Furthermore, previous studies have shown that SBBGR can operate efficiently even at very low temperatures. Consequently, the SBBGR reactor is the most appropriate state-of-the-art technical solution for addressing urban wastewater treatment (Di Iaconi et al., 20149 ). The reactor consists of two units: a biofilter and an aerator.

The biofilter is the reactive part of the plant filled with wheel-shaped plastic elements containing the biomass. The aerator, consisting of a cylindrical steel reactor, is the liquid phase part (i.e. the wastewater); its role is to supply air for the process using a blower connected to a diffuser plate at the bottom of the unit. As the air is supplied into a biomass-free reactor, the often-reported air diffuser clogging of conventional WWTPs is prevented. The biofilter and aerator are hydraulically connected by means of a pump, which continuously recycles the liquid in the aerator through the biomass supporting material of the biofilter. The pilot plant operation is based on a succession of treatment cycles. Currently, this pilot plant is working in Bari (Italy) and treats wastewater from urban areas that have large numbers of tourists and wide fluctuations in the influent parameter quality.

The THERBIOR proposal is to exploit this novel SBBGR system in order to recover/reuse the heat from the aeration tank using a highly efficient tubular heat exchanger (THEx) coupled to a solar-assisted fully off-grid reversible water-source heat pump (SHP). The main goal is to reuse the heat from the already-installed novel SBBGR reactor at CNR-IRSA site for a low-temperature air-conditioning system able to supply an experimental test laboratory (ETL); this will be constructed during the project at the CNR-IRSA site, satisfying the cooling/heating (CH) and domestic hot water (DHW) demand. This system will be backed up by two short-term thermal energy storage units based on Phase Change Materials (PCM), an example of latent heat storage, to ensure the ETL’s year-round CH demand.

Latent heat storage is one of the most efficient ways of storing thermal energy, providing much higher energy storage density with a smaller temperature difference between the stored and released heat compared to the sensible heat storage method (a liquid-based system). In this project, the advantages of an encapsulated solid-liquid PCM will be drawn upon, providing a large heat transfer area and reducing the PCM’s reactivity towards the outside environment while allowing volume control of the storage materials as phase change occurs.

The THERBIOR project will bring together the aforementioned and already-proven technologies to offer an innovative technological improvement to urban water management. THERBIOR will, for the first time, combine and optimize the various components into a multifunctional, integrated system. To successfully disseminate this innovative eco-design, THERBIOR project will lead the elaboration of a business model which systemically evaluates the implementation of the solar-assisted fully off-grid building cooling/heating and wastewater hybrid (SCHW) system, permitting its adoption not only in Mediterranean regions but across the EU as a whole. After obtaining satisfactory results from the developed prototype, we will analyse this novel application’s viability and incorporate it into Almeria’s (Spain) and Bari’s (Italy) network of tourist facilities. Our main goal will be to evaluate how much energy we can gain from a specific urban wastewater network to reduce energy consumption (coming from fossil fuels) for CH and DHW purposes in the tourist buildings located in the studied cities. To evaluate the environmental burden of this integrated system, a Life Cycle Assessment (LCA) and Life Cycle Cost (LCC) analysis will be carried out.